High Efficiency Worm Gear Series Double Enveloping Worm Gear Worm Gearbox

High Efficiency Cone Worm Gear Series Double Enveloping Worm Gear Worm Gearbox Product DescriptionSeries C double envelo

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | CUA/CFA |

| Type | Worm and Wormwheel |

| Manufacturing Method | Rolling Gear |

| Toothed Portion Shape | Worm Gear |

| Warranty | One Year |

| Delivery Time | 60days |

| Applications | Industrial Machinery |

| Transport Package | STEEL CAGE |

| Specification | ISO9001 |

| Trademark | SGR |

| Origin | CHINA |

| HS Code | 8483409000 |

| Production Capacity | 500PCS/MONT |

Product Description

High Efficiency Cone Worm Gear Series Double Enveloping Worm Gear Worm GearboxProduct DescriptionSeries C double enveloping worm gearModel: 100 - 500Ratio: 10 -63Output Torque : 683 - 51180 N.mRating Power : 47/25HP(1.41Kw) - 597HP(448Kw)1, High torque double enveloping worm gear adjust toughest working condition .2,Universal design double enveloping worm gearbox.3, Smooth and noiseless operation double worm gearbox. 4, Higher driving efficiency than traditional worm gear.5, Increasing loading capacity .6, Strict quality test before shipping7, Customized design for various application 8, Long life service period9,suitable price with moderated 10, moderate price & high quality

In a Worm Gearbox, Worm Reduction Gear Box, Worm Speed Reducer and Gear Motor Manufacturer, three to eleven gear teeth are typically in contact with the worm, depending upon the ratio. The increased number of driven gear teeth that are in contact with the worm significantly increases torque capacity also raises shock load resistance. In addition to increasing the number of driven gear teeth in contact with the worm, Worm Gearbox, Worm Reduction Gear Box, Worm Speed Reducer and Gear Motor Manufacturer also increases the contact area on each gear tooth. The actual areas of instantaneous contact between the worm threads and the driven gear tooth are lines. These lines of contact move across the face of the gear tooth as it progresses through its total time of mesh with the worm. The lines of contact in double-enveloping worm gearing are configured to increase the power transmission capability and reduce the stress on each gear tooth.

Working conditions

Two shafts for 90 ° Intersect, input speed must not be more than 1500 rpm.The working environment temperature should range from 0 ~ 40 ° C, when the environment temperature below 0 ° C or above 40 ° C.Before starting the lubricating oil to corresponding heating and cooling, The worm shafts, reverse operation can be positive.

Data sheet on CUW double enveloping worm gear reducer :

| Model | ShaftDia. (mm) | Center Height (CUW) | (CUW) Output shaft Dia. | Power | Ratio | Permitted Torque | Weight |

| (CUW) input Solid(h6) | (mm) | (mm) | (kw) | (Nm) | (KGS) | ||

| 100 | 28 | 190 | 48 | 1.41~11.5 | 10 .25~ 62 | 683-1094 | 42 |

| 125 | 32 | 225 | 55 | 2.42~19.7 | 10 .25 ~ 62 | 1170~2221 | 65 |

| 140 | 38 | 255 | 65 | 3.94~25.9 | 10 .25 ~ 62 | 1555 ~ 3473 | 85 |

| 160 | 42 | 290 | 70 | 4.39~35.7 | 10 .25 ~ 62 | 2143 ~4212 | 120 |

| 180 | 48 | 320 | 80 | 5.83~47.5 | 10 .25 ~ 62 | 2812 ~ 5387 | 170 |

| 200 | 55 | 350 | 90 | 7.52 ~61.2 | 10 .25 ~ 62 | 3624 ~6859 | 220 |

| 225 | 60 | 390 | 100 | 9.9~81.4 | 10 .25 ~ 62 | 4872 ~ 9224 | 290 |

| 250 | 65 | 430 | 110 | 12.9 ~105 | 10 .25~ 62 | 6284~11892 | 380 |

| 280 | 70 | 480 | 120 | 16.9 ~ 138 | 10 .25 ~ 62 | 8347 ~ 15820 | 520 |

| 315 | 75 | 530 | 140 | 22.5 ~183 | 10 .25 ~ 62 | 11068~ 19450 | 700 |

| 355 | 80 | 595 | 150 | 30~245 | 10 .25 ~ 62 | 14818 ~28014 | 1030 |

| 400 | 90 | 660 | 170 | 32.1 ~261 | 10 .25 ~ 62 | 15786~29918 | 1400 |

| 450 | 100 | 740 | 190 | 42.6 ~347 | 10 .25 ~ 62 | 20998~39881 | 1980 |

| 500 | 110 | 815 | 210 | 54.9 ~ 448 | 10 .25 ~ 62 | 27097~51180 | 2700 |

Advantage: The advantage of Sgr High Efficiency, Low Noice Cone Worm Series Worm Gearbox design are dramatic. First, the total load is divided among more individual gear teeth, and the load is further divided where teeth support two lines of contact. This superior load distribution greatly increases load carrying capacity. Second, the improved torque throughput allows a smaller reducer to produce the same amount of torque, resulting in size and weight savings.Double-enveloping worm gearing can carry loads that would require much larger and heavier cylindrical worm gearing.

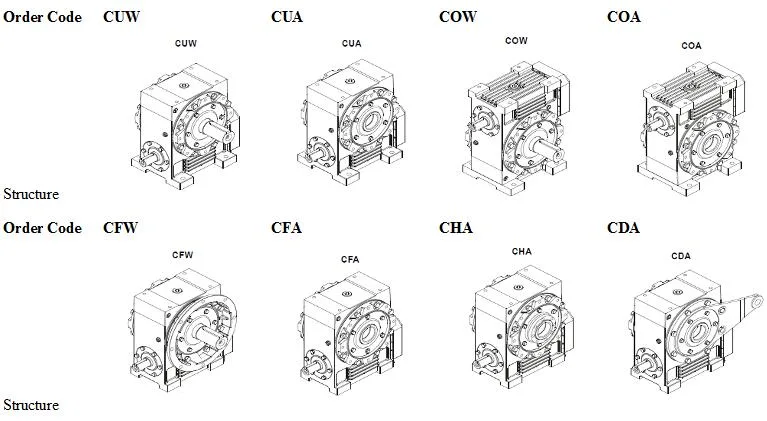

Double-enveloping worm gearbox figure :

(Click on picture for more information)

Packaging & ShippingPackage :

SGR gearbox use standard wood case per gear motor | gear unit.

Shipping :

According to Customer requirement, we delivery products by different transport, Sea shipping, Air Transportation / Express or Truck transportation etc.

You Appoint, We Service!

Our ServicesWith all our activities DNV-ISO 9001, SGS -certified, we stand for top-quality service. Entrusting your gearboxes to the care of our Services.

Help protect your gearbox from wear and grinding, SGR gearbox converts torque reliably and efficiently.We customize our SGR planetary gear units, double enveloping worm gearbox, helical gear motor, modular design helical gear unit, worm gearbox, cycloidal gearbox etc to fit your application and meet your needs. These features enable a reliable and safe service life of over 200 000 operational hours. Our customers have been placing their trust in SGR gear units since 1997. More than 500 000 gear units of our gearbox are in use reliably around the world, in many cases under very harsh conditions.

Related Products

-

![1-4 Stage High Quality Planetary Speed Reducer for Engineering Machinery]()

1-4 Stage High Quality Planetary Speed Reducer for Engineering Machinery

-

![High Precision Low Noise Spur Gear Planetary Gearbox]()

High Precision Low Noise Spur Gear Planetary Gearbox

-

![Planetary Transmisson Planetary Gearbox with Hydraulic Motor Can Replace Brevini]()

Planetary Transmisson Planetary Gearbox with Hydraulic Motor Can Replace Brevini

-

![Right-Angle Planetary Commutator Reducer Angle 90 ° Hole Shaft Output 400W Servo Motor Gearbox Steering Gear]()

Right-Angle Planetary Commutator Reducer Angle 90 ° Hole Shaft Output 400W Servo Motor Gearbox Steering Gear